Radiant Panel Heaters

Radiant panel heaters can be mounted to radiate in any direction and can reliably operate with no reduction in output over the life of the heater

Global Support

Support and spares available around the world.

Product Series: Radiant Panel Heaters

Wide area radiant panel heaters can be mounted to radiate in any direction and can reliably operate, with no reduction in radiant output over the life of the heater. The lightweight building block approach allows for a modular installation which is easily expandable. One-piece bonded construction resists damage from vibration and shock. These radiant panel heaters also have a lower operating cost with up to 80% of the input energy transmitted to and absorbed by the work material.

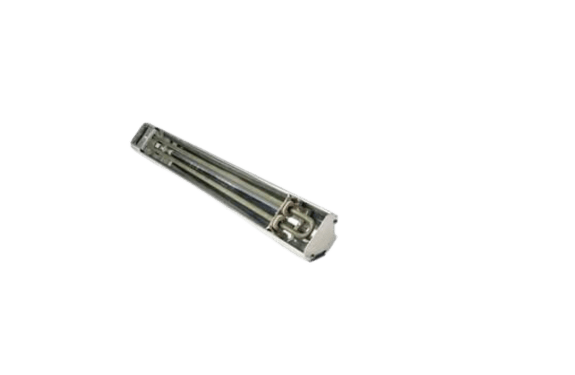

CPH Wide Area Radiant Panel Heater

CPL & CPLI Wide Area Radiant Panel Heater

Easy Mounting — Heater can be mounted to radiate in any direction.

Reliable Operation — No reduction in radiant output over life of heater.

Uniform Radiation Pattern Assured with a wide flat infrared surface versus the line pattern given in normal radiant heaters. This eliminates uneven heating of the work and allows uniform heating of a stationary surface such as in an indexing process.

External Reflectors Not Required — The refractory board and bulk insulation behind the heating element help prevent back heat loss. This eliminates the need for external reflectors.

One-Piece Bonded Construction resists damage from vibration and shock.

Overtemperature Control — These units should be controlled such that overheating and premature failure do not occur.

Additional Sizes and Ratings — Contact your Local Chromalox Sales office for price and availability.

Lower Operating Cost with up to 80% of the input energy transmitted to and absorbed by the work material. The maximum amount of radiant energy is transferred to the work with very low heater convection losses. Typical installation distance of two to four inches from the work surface significantly reduces the energy input.

Costly Downtime Minimized — There is no deterioration of the output radiation level with heater life and no reflectors to clean which could cause downtime and increased maintenance costs. The unit is resistant to vibration because of the compact homogeneous construction.

Easy Installation — The light weight building block approach allows for a modular installation which is easily expandable. These rugged panels can be mounted in any direction.

Repeatable Process Performance Assured — Used with closed loop control, the system automatically compensates for ambient temperature ranges and line voltage fluctuations. Maximum energy transfer requires matching the peak wavelength output to the specific material absorption characteristics. Because the peak wavelengths of the flat surface heater are repeatable and adjustable, the quality output of the process is assured.

CPHI High Intensity Quartz Faced Radiant Panel Heater

Highest Watt Density Available of any Medium Wave Infrared Radiant Panel Heater — Due to thermal and electrical properties of the grooved quartz face plate, CPHI has the highest watt density (5.76 kW/Ft2) of any medium wave infrared radiant panel heater.

Uniform Radiation Pattern Assured with a wide flat infrared surface versus the line pattern given in normal radiant heaters. This eliminates uneven heating of the work and allows uniform heating of a stationary surface such as in an indexing process.

Lower Operating Cost with up to 80% of the input energy transmitted to and absorbed by the work material. The maximum amount of radiant energy is transferred to the work with very low heater convection losses. Typical installation distance of two to four inches from the work surface significantly reduces the energy input.

External Reflectors Not Required — The refractory board and bulk insulation behind the heating element help prevent back heat loss. This eliminates the need for external reflectors.

Costly Downtime Minimized — There is no deterioration of the output radiation level with heater life and no reflectors to clean which could cause downtime and increased maintenance costs. The unit is resistant to vibration because of the compact homogeneous construction.

Easy Installation — The light weight building block approach allows for a modular installation which is easily expandable.

Note — CPHI heaters mount only so that the coil direction is in the horizontal plane.

Repeatable Process Performance Assured — Used with closed loop control, the system automatically compensates for ambient temperature ranges and line voltage fluctuations. Maximum energy transfer requires matching the peak wavelength output to the specific material absorption characteristics. Because the peak wavelengths of the flat surface heater are repeatable and adjustable, the quality output of the process is assured.

Technical Resources for Radiant Panel Heater

Process Radiant Heater Design Guide

Process Radiant Heaters Overview

CPL and CPH Installation Manual

CPL, CPLI, & CPH Wide Area Radiant Panel Heater

CPHI High Intensity Quartz Faced Radiant Panel Heater

Request a Quote

From high temperature gas heating to superheated steam and super-critical water processing, Chromalox is the leading partner for all process heating solutions.