SRP Self-Regulating Heating Cable

(Process Temperature)

Process Temperature Maintenance to 230°F (110°C)

Energy Efficient

Optimized for efficiency gains across your processes.

Quick Install

Designed for faster installation to reduce your labor time.

Self-Regulating

Over temperature conditions are minimized.

About SRP Self-Regulating Heating Cable

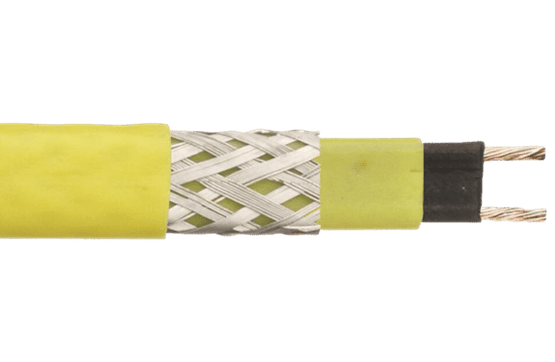

Chromalox SRP self-regulating heating cable provides safe, reliable heat tracing for process maintenance applications to 230°F (110°C) or freeze protection of pipes / tank with high heat losses. Constructed of industrial grade 16 AWG buss wire with a tinned copper braid, SRP ensures operating integrity most hostile industrial environments.

WARNING — A ground fault protection device is required by NEC to minimize the danger of fire if the heating cable is damaged or improperly installed. A minimum trip level of 30mA is recommended to minimize nuisance tripping.

Request a Quote: Self-Regulating Heating Cable

Chromalox heat trace solutions offer a safe, reliable and efficient way for freeze protection and process maintenance of pipes, valves, and tanks in the most extreme conditions.

SRP Self-Regulating Heating Cable (Process Temperature)

+ Self-Regulating heat trace, Energy Efficient

+ 16 AWG Buss Wire

+ Circuit Lengths to 750 Feet

+ Process Temperature Maintenance to 230°F (110°C)

+ Maximum Continuous Exposure Temperature, Power Off, 275°F (135°C)

+ Available in 5, 10, and 15 Watts per Foot

+ 120 and 208-277 Volts Available from Stock

+ Industrial Process Maintenance Applications

+ Approximate Size .47 in. W x .20 in. H

+ Min. Bend Radius 1-1/8 "

+ For use on Metallic Pipes

+ Consult Factory for use on Plastic Piping

+ Factory Mutual (FM) approved for ordinary areas

+ FM, ATEX and IECEx approved for hazardous (classified) areas when used with U Series and DL accessories

+ Energy efficient, self-regulating SRP uses less energy when less heat is required

+ Easy to install, SRP can be cut to any length (up to max circuit length) in the field

+ SRP features lower installed cost than steam tracing, less maintenance expense and less down time

+ SRP can be single overlapped without burnout, which simplifies heat tracing of in-line process equipment such as valves, elbows and pumps

+ Because SRP is self-regulating, over-temperature conditions are minimized

+ Chromalox U-Series Connection Kits reduce installation time

Applications

Formats the Html codes, Format Fix the Html to be XHtml compliant, Fix Write Validate that the text is XHtml compliant, Validate Proofing.

+ Freeze Protection

+ Freeze Protection, High Exposure Temperature

+ Process Maintenance, Low Temperature

+ Process Maintenance, High Temperature

Features of SRP Cable

Max. Maintenance Temp. (°F) 225

Max. Exposure Temp. (°F) Power Off 275

Max. W/Ft. 15

Max. Circuit Length (Ft.) 55-750

Buss Wire Size 16

Voltages 120, 208-270

Hazardous Ratings Yes

Usable on Plastic Pipe No

Cut-to-Length in Field Yes

Field Splicable Yes

Can be Overlapped Yes

Output Varies with Temp. Yes

Varies Output Along Length Yes

Accessories D/UL

Monitor Wire Available Yes

SRP Corrosion Selection Guide

Moisture C, CT

Aqueous Solutions of Inorganic Compounds CT

Liquids Organic Chemicals Acids or Bases CT

Acids or Bases CT

C - Tin-Plated copper metallic braid for additional protection and ground path

CT - Fluoropolymer corrosion resistant over-jacket over braid for hostile/corrosive environments

This is a recommendation guide. Chromalox cannot warrant any Electric Heat Trace against failure by sheath degradation if such failure is the result of operating conditions beyond the control of the heater manufacturer. It is the responsibility of the purchaser to make the ultimate choice of sheath material based on knowledge of the chemical composition of the corrosive solution, character of materials entering the solution, and controls which maintains the process.

![Heat Trace Product image: CPR Self-Regulating Heat Trace Cable [stripped]](https://content.chromalox.com/-/media/chromalox/products/heat-trace/cpr_commercial_sr_ht.ashx?rev=7c4e4f0c21ac423bb0f2890ad2d5167a&extension=jpg%2cgif)

![Heat Trace Product image: Self-Regulating Heat Trace Cable [stripped]](https://content.chromalox.com/-/media/chromalox/products/heat-trace/cpm_sr_medium_temp.ashx?rev=258c20e202844efa920dbd556be778b8&extension=jpg%2cgif)